Reclaimed Water Facility

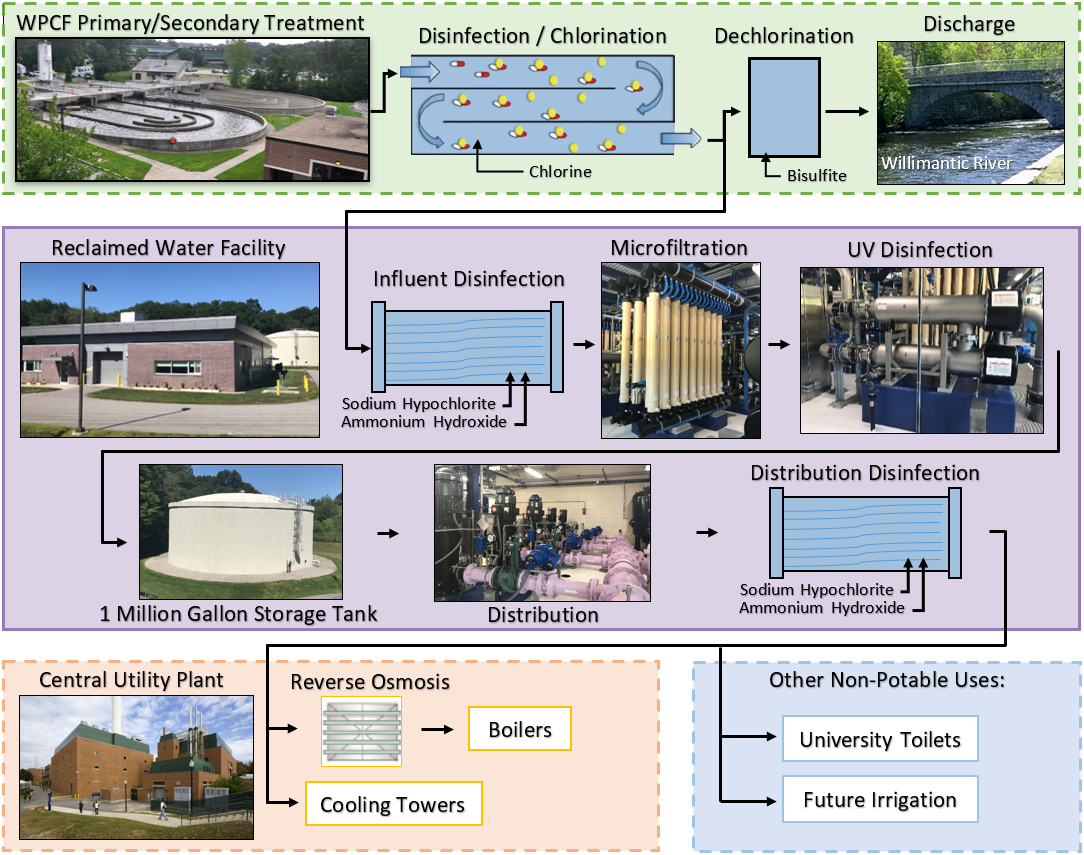

The Reclaimed Water Facility (RWF) uses a tertiary treatment process for the University’s waste water. This process uses microfiltration and ultraviolet disinfection, which will allow UConn to divert a maximum of 1 million gallons of non-potable – not drinkable – water each day to meet the campus needs that don’t require fresh water. One of these needs is at the Cogen power plant, which uses anywhere between 250,000 and 450,000 gallons of cooling water per day. The facility allows the University to use the treated non-potable water to meet this need instead, replacing the need to pump and treat hundreds of thousands of gallons of potable water from our two major water supply well fields. The Reclaimed Water Facility is currently fully operational and processes hundreds of thousands of gallons of water each day for use at the Cogen Facility, Innovative Partnership Building, and Engineering and Science Building.

For more information please visit the following links below:

Reclaimed Water Facility: News Articles

Eye on Sustainability: UConn Reclaimed Water Facility Shows Campus' Green Side

The Reclaimed Water Facility at the University of Connecticut sits right between two other critical utility plants on the campus.

It receives secondary effluent from the university’s Water Pollution Control Facility (WPCF) and it delivers reclaimed water to the Central Utilities Plant (CUP) for use in the cooling towers and boilers. About 20 to 60 percent of water used there returns to the WPCF.

Rob Scott, project manager with Woodard & Curran, leads a staff of four in fulfilling the Reclaimed Water Facility’s role in the university’s semi-closed water loop. “Close communication and cooperation among the three facilities is essential,” says Scott. “Any operational change or issue at one facility has potential to affect water quality and operations at the other two.” Continue reading

Playing Catchup: the slow and steady march of water reuse in New England

Loading...

Loading...